Published: 26 Dec, 2025 | By Solar

You're about to drop serious money on solar panels. These things will be stuck on your roof for 30 years, maybe more. So, let us ask you something: what exactly are you paying for? Most salespeople throw efficiency numbers and wattage stats at you. Those matter, obviously. But they won't tell you if your panels will still be pumping out power in 2045.

Want to know what actually determines that? The guts of each module. If you're shopping for solar panels for residential roofs, especially an on-grid solar system, understanding these parts is how you avoid getting burned.

Let's break down six core solar panel components. Not because you need an engineering degree, but because this knowledge stops you from making Rs. 3 lakh mistakes.

1. The Solar Cell: Where Electricity Happens

Dead centre of every panel sits the solar cell. This is where the magic happens. Sunlight hits it, light particles (photons) get absorbed, and boom, you've got Direct Current electricity flowing.

- Material: Pretty much every panel today uses Monocrystalline Silicon. It's silicon that's been purified and grown into one giant crystal structure. Why should you care? Because electrons zip through it with barely any resistance. Less resistance means higher efficiency. Got a small roof? That efficiency could be the difference between covering 60% of your power needs or 90%.

- Modern Tech: Spectra Solar Power and other serious manufacturers use TOPCon or PERC cell designs. These aren't buzzwords. They're engineering upgrades that push efficiency past 23%. More power from the same space.

- Manufacturing: Pure silicon is grown into a massive cylindrical crystal. That crystal gets sliced into wafers thinner than a credit card (160 to 180 micrometres). These wafers get textured microscopically to trap light instead of bouncing it back. Then they're chemically treated to create an internal electric field. That field grabs electrons knocked loose by sunlight and shoves them out as current.

Understanding solar panel function at this level shows you why cheap manufacturing kills performance.

2. Protective Glass: Your First Defence

This isn't window glass. It's doing real work.

- Specs: Quality panels use tempered, low-iron glass at 3.2mm to 4mm thick. Tempering means it's been cooked at high heat so it can take hail hits, wind pressure, and impact without breaking. Low-iron means it's clear as water, not that slightly green tint you see in regular glass. More clarity equals more light getting through.

- The Coating: Good glass has an Anti-Reflective coating. Cuts down light bouncing off the surface. Maybe only 2-3% more light gets in, but over 25 years? That's real power you're not losing.

- Defence: Glass stops moisture. Once water sneaks past it, your cells start corroding. The best solar panel company in India knows this, which is why they don't cheap out here.

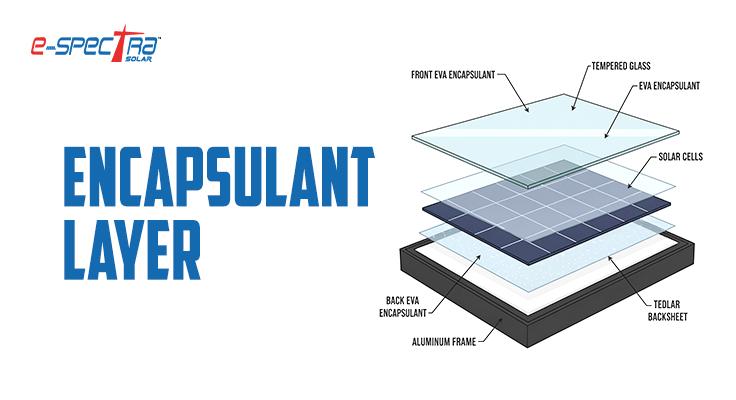

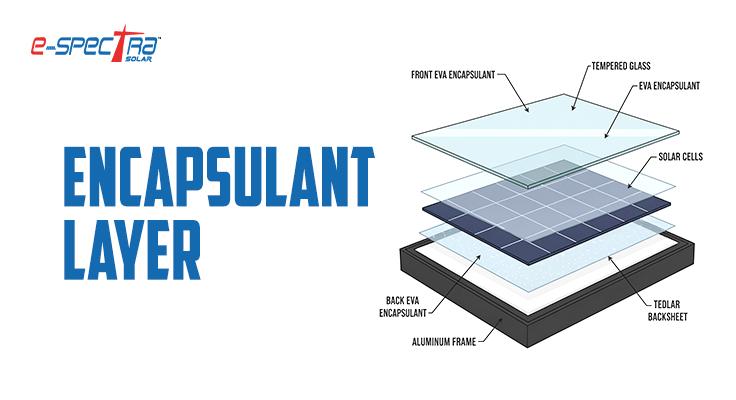

3. Encapsulant Layer: Nobody Mentions This Part

Between your glass and cells, there's a thin polymer film. Same thing between cells and the back layer. Buyers rarely hear about it. But it's absolutely crucial.

- Material: Old panels used EVA film. Better ones now use POE, which laughs at humidity and heat.

- Job: During manufacturing, these films get blasted with heat and pressure. They melt, glue everything together permanently, then harden. Creates an airtight seal, keeping moisture, dust, and air away from the delicate bits inside.

- Failure: Cheap encapsulant? You get delamination where layers peel apart. Or moisture seeps in, causing brown "snail trail" corrosion across your panel. Both trash your power output. When you're paying for solar panel maintenance services, inspectors should be checking this.

4. Back Sheet: The Rear Guard

Bottom layer of your panel. Two critical jobs.

- Construction: Multi-layer polymer film, usually PVF or fancy polyester. These materials survive years of UV beating and block moisture.

- Purpose: Safety first—insulates the panel so DC voltage doesn't leak. Second, environmental protection—a final barrier against UV and moisture creeping up from your roof. India's climate is brutal. Coastal salt spray, monsoon floods, desert heat. A garbage back sheet cracks and peels. Then your cells are exposed and slowly dying.

5. Aluminium Frame: The Skeleton

The frame around the edges isn't decoration. It's structural.

- Treatment: Anodised aluminium. Anodising is a chemical bath that builds a protective oxide coat on the metal. Makes it corrosion-proof, even near oceans where salt air normally eats metal alive.

- Strength: Your frame handles 5400 Pa of downward force. That's simulating heavy snow or brutal wind. Also has mounting slots, installation holes, and drainage grooves so water doesn't pool.

6. Junction Box and Connectors: The Connection Point

Small weatherproof box stuck to the back. Where cell connections meet and your panel links to your system.

- Box Specs: Rated IP65 minimum. Completely dust-sealed and water-jet proof. Inside are bypass diodes, possibly the smartest safety feature in the whole panel.

- Diodes: When shade hits part of your panel (tree, bird, whatever), that shaded chunk resists current flow. Without bypass diodes, current tries forcing through anyway, heating those cells until they're cooked. Bypass diodes sense resistance and instantly reroute current around the problem area. Saves your panel's life and minimises power loss.

- MC4 Connectors: Standard weatherproof plugs linking panels together in a string. Secure, corrosion-proof connections. Every on-grid solar system uses these.

Checking Quality When You Buy

You know the solar panel components list now. You understand what are the major components used for making solar panels. How do you verify quality while shopping?

- Degradation Rates: Most honest quality metric. Demand a warranty guaranteeing under 0.5% degradation yearly. Means you're still getting 87%+ original output after 25 years.

- Specific Assessments: Don't accept generic estimates. Use Spectra Solar Power's Solar Calculator—factors in your actual roof angle, local sun patterns, consumption, and shade. Moves you from guessing to real planning.

- Maintenance Planning: Great panels still need care. Professional cleaning and junction box checks aren't optional for peak performance and safety. Before signing, ask about solar panel maintenance services. Check their Annual vs. Monthly Solar Maintenance Plan options. Learn solar panel maintenance tips upfront so you know total ownership costs.

Real Talk

Learning about components used in solar panel construction protects your hard-earned money. When you know what makes quality panels (pure monocrystalline cells, low-iron tempered glass, solid encapsulant, tough back sheet, corrosion-proof frame, engineered junction box), you spot garbage before it becomes your problem.

Panels from a legit best solar panel company in India cost more upfront. But weigh that against replacing dead panels in year 12. Focus on these six parts, understand solar panel components and functions, and your investment actually delivers for 25 to 30 years. Solar panels for residential roofs aren't appliances. They're a 30-year tech partnership. At

Spectra Solar Power, we're upfront about what's inside our panels because smart customers make better choices. Every single module we install comes with top-grade components used in solar panel construction. We back everything with warranties that actually matter, plus full maintenance backup when you need it.

Ready to stop guessing? Punch your details into our Solar Calculator and get numbers specific to your property. Or just call our team. We'll walk you through exactly how picking the right components now saves you lakhs over the next 25 years.